Specialized in the manufacture of solid rivets, aeronautical screws and lockbolts.

A Century of Expertise Dedicated to Innovation

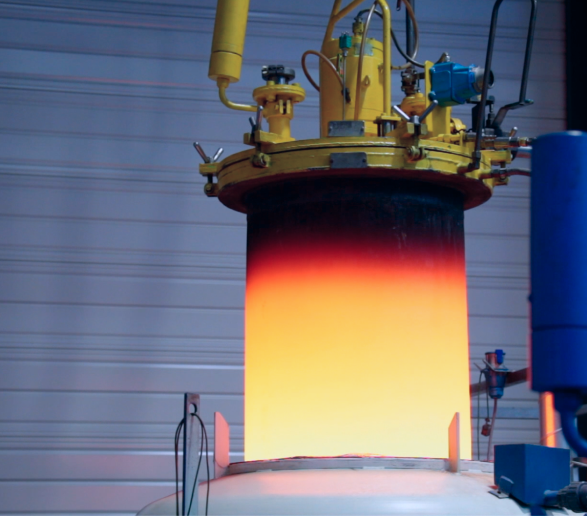

Surface treatment plant offering subcontracting services

Cassette feeding systems company.

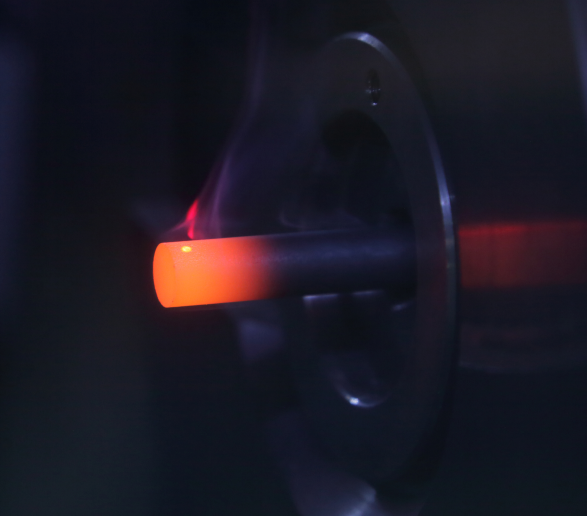

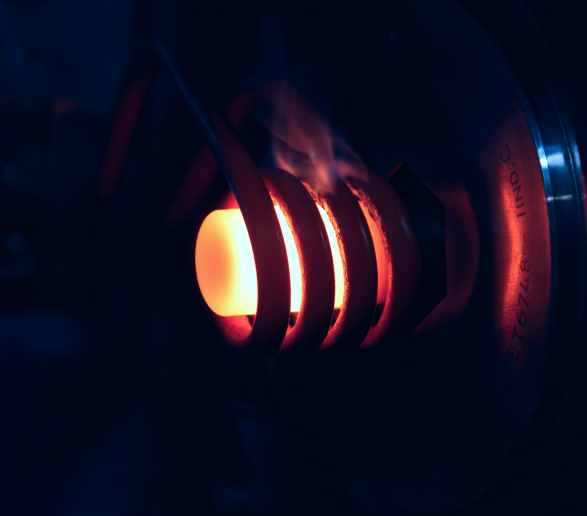

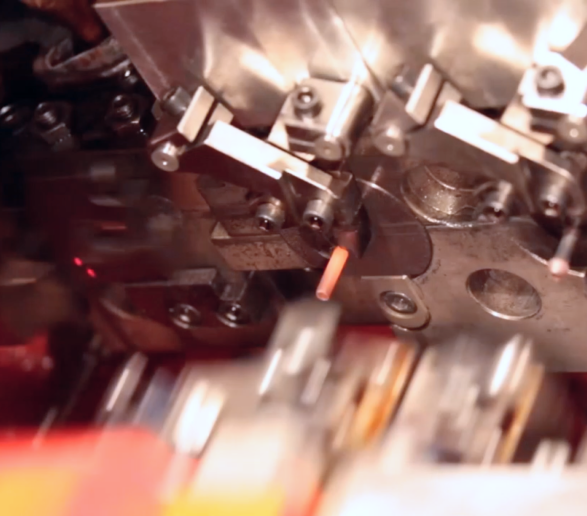

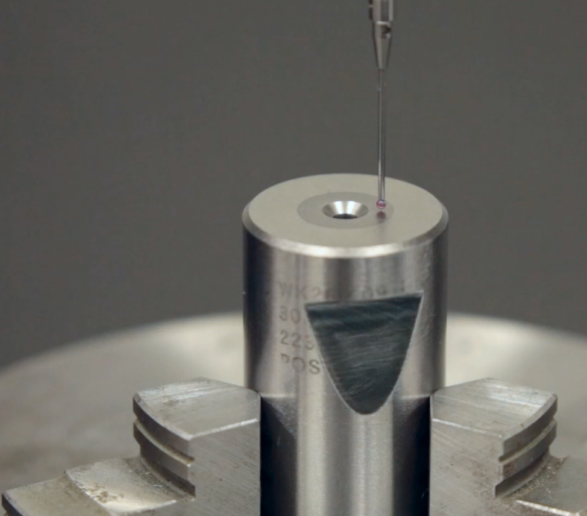

AHG strives to integrate the maximum number of processes required to manufacture its parts, with a view to improving quality while reducing costs and lead times. Above all, AHG's expertise and innovative spirit are recognized by major players in the aeronautics industry. Below is a list of our processes: